Craftsmanship

and High Technology

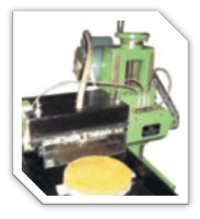

Polishing Machine

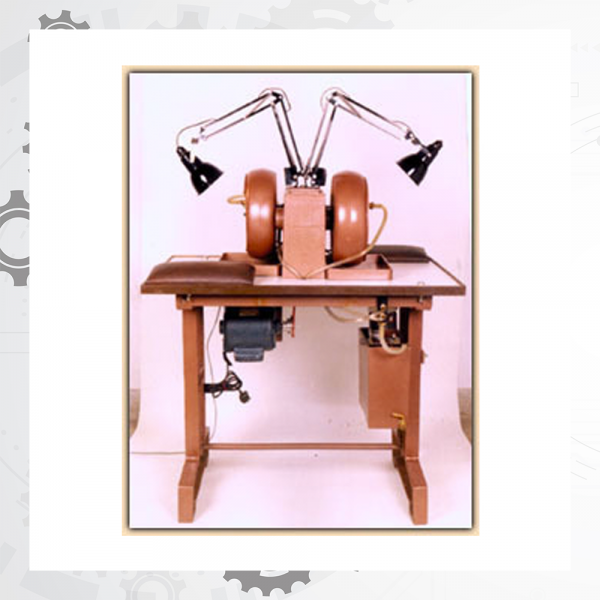

Grinding Machine

AnandGems- Pioneer in Lapidary Machine Supplies & Equipment

We, the third generation jewelers and lapidary owners of Jaipur, the Gem Capital of India are proud entrepreneurs who have used engineering skills and our extensive knowledge of Lapidary and Jewelry operations to develop and market lapidary machines, jewelry making machines, hand tools, and a large variety of gems & jewelry.

Lapidary Equipment

Slab Sawing Machine

$1,600.00

Multiple Blades Sawing Machine

$7,500.00

PreForming Machine

$700.00

Girdle Shaping & Calibrating Machine

$1,450.00

Computerized Bruting Machine for Round Shape

$5,000.00

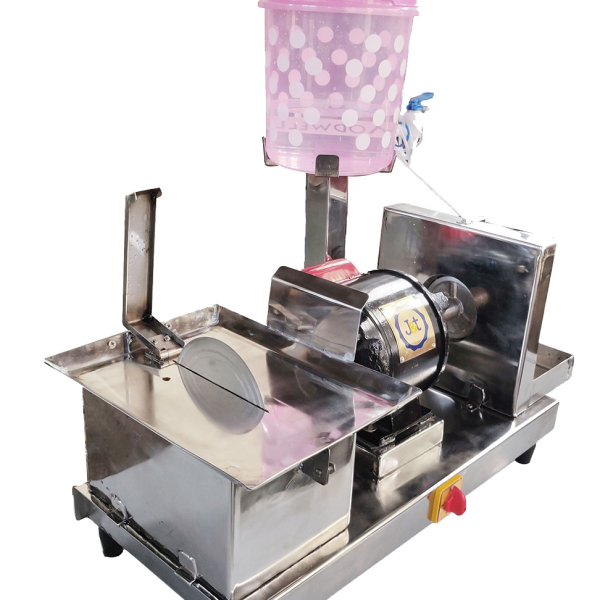

Cabochon Shaping cum Calibrating Machine

$1,700.00

Faceting & Polishing Machines

$750.00

Faceting Machines – Jamb Peg

$700.00

Faceting & Polishing Machines – 2 Operators

$1,100.00

Faceting & Polishing Machines – 4 Operators

$1,600.00

Anand Gems- Pioneer in Lapidary Machines and Lapidary Equipments

Excellent Lapidary Machine Support

Consult our specialists for help with an order, installation, or usage of Lapidary Machine & Lapidary equipment

Maintenance of Machines

Contact us for orders or customization requests. We are happy to give you the best price for laipdary machines

Wide Range of Lapidary Equipments

Find complete range of gem equipment & lapidary machines for your business.

Lapidary Supplies

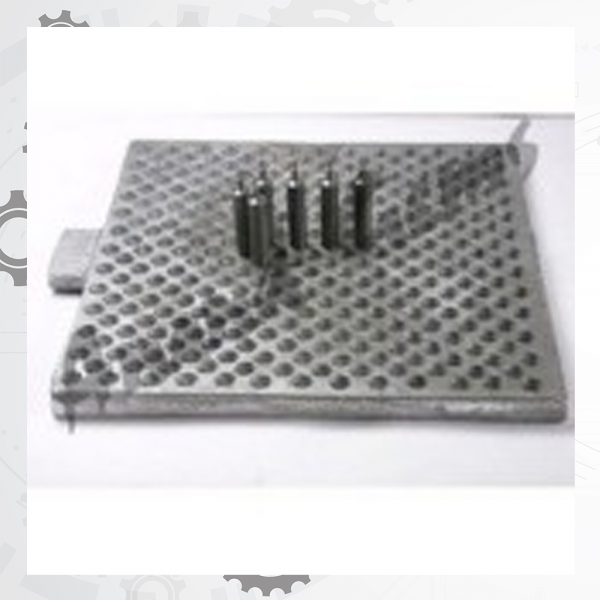

Base Plate for Grinding or Grit Laps

$5.00

Brass Dop Sticks

$4.00

Brass dopsticks are mainly used with our machine models AEW-FPID, AEW-FPIT(2), AEW-FPIT(4), AEW-FPIT(6). The stone is glued on this stick for faceting and polishing on our machines. This stick has an indexing attachment which comes in the following options:

- 8 Divisions

- 10 Divisions

- 12 Divisions

- 14 Divisions

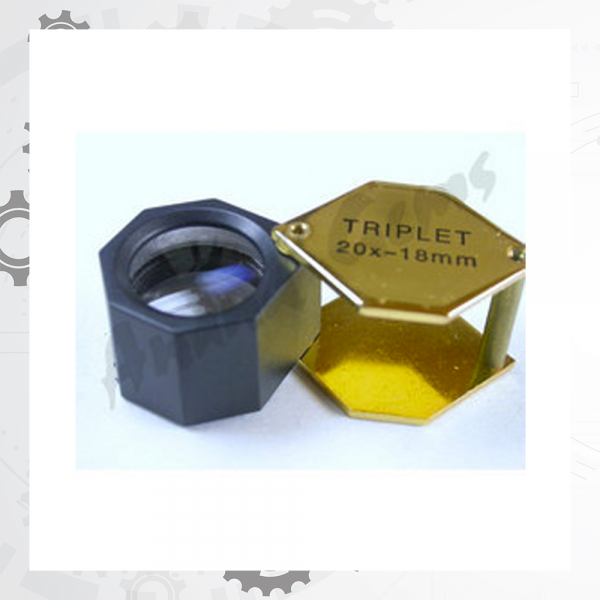

Dial Gauge for Measuring Gemstones

$45.00 – $57.00

Dop Stick Stand

$25.00

This dop stick stand is commonly used with our machine models AEW-CSM and AEW-FPK. Also used for keeping the dopsticks straight while heating them. This stand has multiple holes of the size of dopsticks on the top part and very small holes on the bottom part for the heat to pass through while heating

Dop Sticks – Wooden – Pre Glued

$13.00

Dopping Glue – Two Epoxy Ressin

$10.00

Dopping Wax

$10.00

Faceting or Grinding Tool – Concave Machine

$25.00 – $35.00

Gemstone Assoritng Tray

$10.00 – $18.00

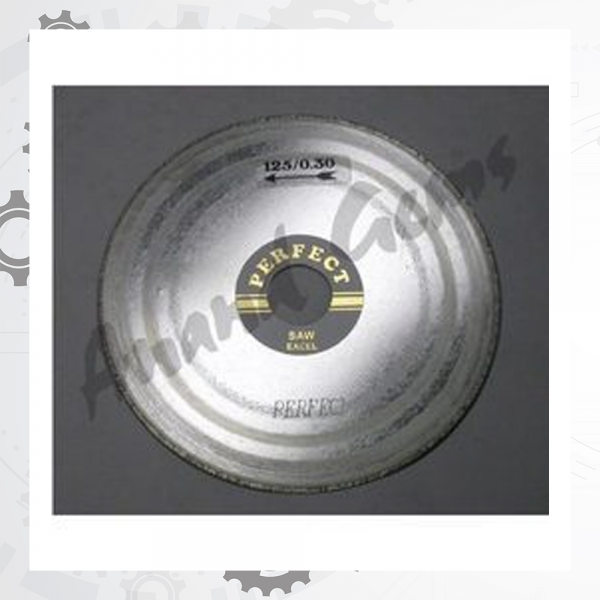

Gemstone Sawing Blades

$5.00 – $20.00